Manufacturing

Here is an overview of our manufacturing plant and our production process.

Infrastructure

Intech Forge India Pvt Ltd is India’s leading manufacturer & exporter of LPG Cylinders, Valves, Steel products,

Coal Products, etc. It has a state-of-the-art facility that high quality and reliable products.

- They are serving the oil and gas industry for over 3 years.

- The manufacturing plant is accredited to manufacture cylinder conforming to major international standards.

- Intech is authorized to manufacture and supply the cylinders as per Indian government standards.

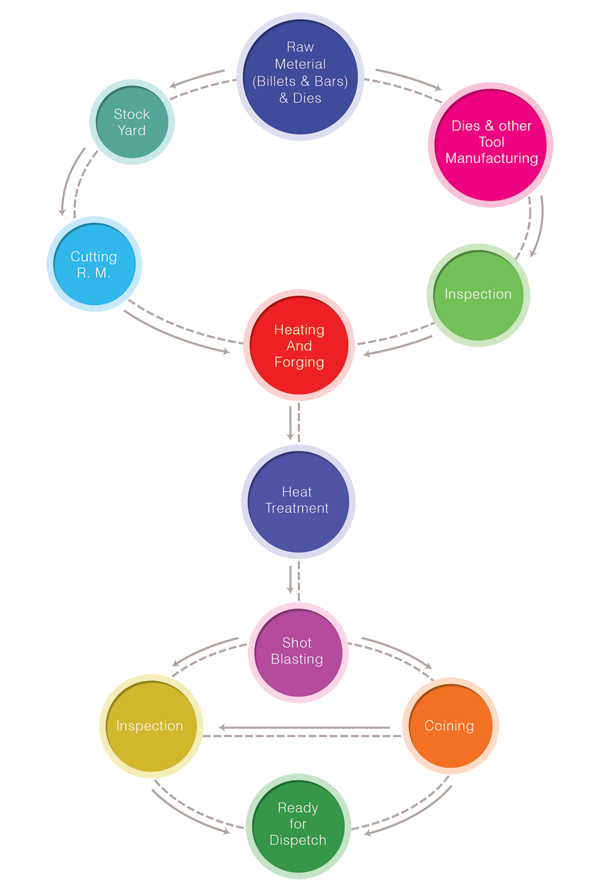

Process Flowchart

The layout of the plant has been designed in such a way so that all the manufacturing activity can be done under one roof to facilitate easy &

quick flow of processed material from one stage to another stage of processing to reduce Manpower, Time, and Cost.

Quality

Intech strongly believes that quality forms the backbone of any organization. For them, it forms the bottom line for all functions and operations which helps them in achieving world-class products. Through their high-quality parameters, they exceed their customers’ expectations every single time and reinforce their trust. By using operational quality tools like cause-and-effect diagram, PDCA, check sheet, control chart, histogram and pareto analysis they leave no stone unturned in ensuring delivery of quality products of the highest order.

At Intech, customer focus and quality go hand in hand and play utmost importance. They think beyond customer satisfaction and achieve customer delight through excellence in manufacturing process and development of products. It is their proactive approach towards quality that helps them in responding quickly to customer requirements, technological shifts and price competitiveness.

Few initiatives that have been undertaken are:

- Variation reduction in our processes

- Flawless product launches

- Robust manufacturing system in line with the best-in-class

- Continuous improvement using 6-sigma methodology

Through these initiatives, they have successfully achieved customer delight and exceptional quality standards. They have simultaneously increased their competitiveness and reputation while adhering to the latest manufacturing compliances. Their focus on productivity and production efficiency has helped them reduce wastes resulting in cost reductions.

They value the voice of customer in terms of performance, quality, design and cost competitiveness. Use of sophisticated inspection and testing equipment help them to deliver right solutions to customer at the right time. Their zero-defect mentality reiterates their commitment towards quality and customer delight.